- PLASTICOLOR

-

1. PLASTICOLOR ---solutions for colorizing the plastic profile

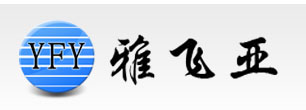

PLASTICOLOR is a new product we produce with the machine by our own design on the basis of German technology. This product can be used to manufacture new-style plastic alloy material with colorized PCPO color plane.It has lots of advantages. Good compatibility with PVC, Excellent weather resistance ,Outstanding Surface and Gloss High hardness.

2. Comparison between plasticolor and other methods in colorizing

| methods | advantage | shortcoming |

| colour mixturing in whole | Simple manufacturing technique | Uncontrollable in color; Bad weather- resistance |

| spraying | Large selectivity in color; Flexible in execution | Waste a lot in painting; Bad quality in surface |

| coating | Flexible in execution; Easy in operation | coating is easy to drop; Outdoor unsuitable |

| Co-extrusion by plasticolor | Large selectivity in color; Flexible in execution ;Easy in operation | All the shortcomings above are improved |

-

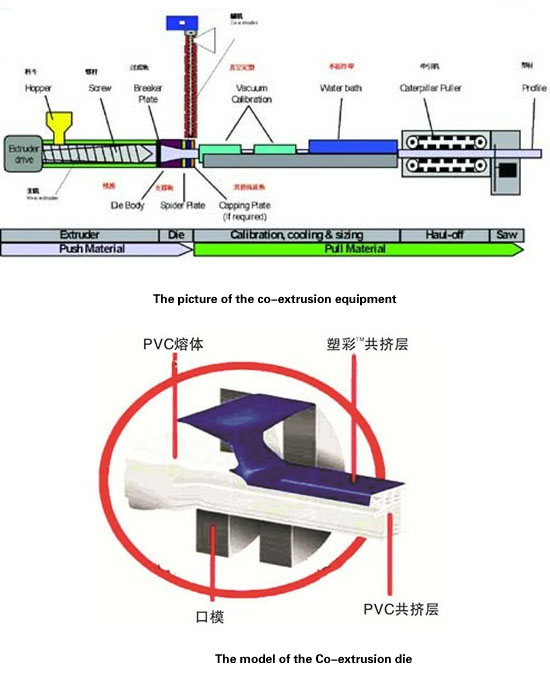

3. the co-extrusion equipment used in plasticolor

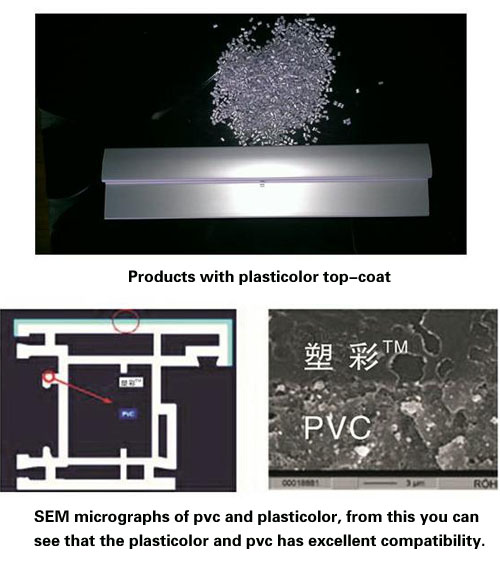

There are two extruders used for extrusion, one is for the extrusion of the white Polyvinyl chloride profiled material, the other is for the plasticizing and extrusion of plasticolor. Normally, the latter is a single screw extruder with small diameter. In the production process, the melt of the two parts extruded by one headpiece will be pulled into the stock mould and water box for cooling. After cooling, we can get the qualified colorized profiled material.

-

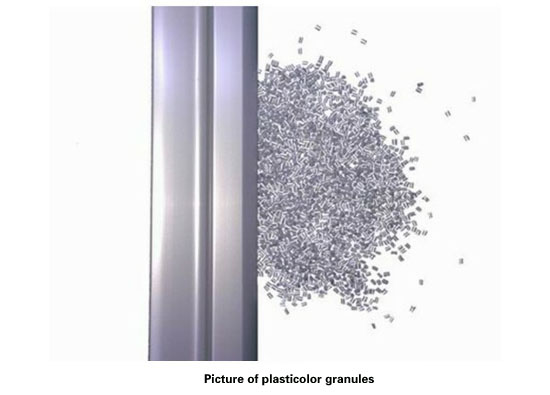

4.properties of plasticolor

Appearance: granulated solid

Smell: no special smell

Melting point: no specific melting point, melting gradually along with the change of temperature(130 ºC to 150 ºC).

Proportion: 1.19g/cm3

The solubility of solvents: water-fast, soluble in solvents such as chloroform.

-

5.package and other notes

1 package: 25 kg in a paper-plastic composite bag or vacuum packing in a 25 kg Aluminum film bag.

2 notes: before using this product, please predry for 4 hours in 85 ºC. In the production process, to insure the quality of the products, please keep the environment dustproof, moistureproof in case of mixing.

3 Recommended Processing Temperature:

| Heating zone | first zone | Second zone | Third zone | Fourth zone | confluence zone | dies |

| Temperature stated | 180—195 | 185—195 | 185—200 | 185—200 | 190—205 | 200—210 |

- Notice: it is the temperature suggested, in the reality, please subject to the actual requirements.

-

6. the color of plasticolor